Allergies are becoming more common, with hospital admissions for allergic reactions rising by 33% in the last five years. As a food producer, you have a legal obligation to ensure your products are free from undeclared allergens. Discover how Vikan's range of color-coded tools and Site Survey can help you meet these requirements.

Allergen control – why is it important?

Effective allergen management is essential in any food business. Integrating it into your overall food safety system is key to its success. Ignoring or mismanaging this requirement can lead to serious consequences, from consumer discomfort to life-threatening reactions. Allergies are on the rise globally, with 1 in 50 children in the UK having a nut allergy. Peanut allergies have tripled in the past decade, and hospital admissions due to allergic reactions have increased by 33%. Every year, around 10 deaths in the UK are linked to food allergies, particularly among those under 25.

It is crucial that everyone involved in food production understands what allergens are, why they need to be controlled, and how best to manage them.

What are allergens?

An allergen is a substance that causes an allergic reaction when the immune system overreacts to something normally harmless. The EU currently lists 14 allergens, including:

- Gluten

- Sesame

- Nuts

- Crustacean

- Eggs

- Fish

- Mustard

- Milk

- Celery

- Peanuts

- Soya

- Shellfish

- Lupins

- Sulphite

Allergen control – Legal and Global food safety Standard requirements

If your site produces foods containing any of these allergens or non-allergenic foods, you must ensure proper labeling and that non-allergenic products are free from allergens. Key regulations include:

- Regulation (EC) No 178/2002 - General Food Law Regulation

Prohibits unsafe food from being placed on the market - EU Food Information for Consumers Regulation (EU) No. 1169/2011

Provides information about the 14 allergens listed by the EU

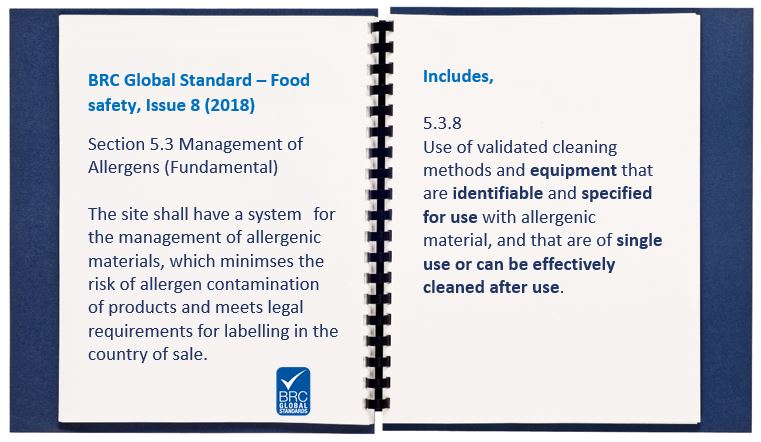

Global food safety standards also require effective allergen control.

Allergen control – How can it be achieved?

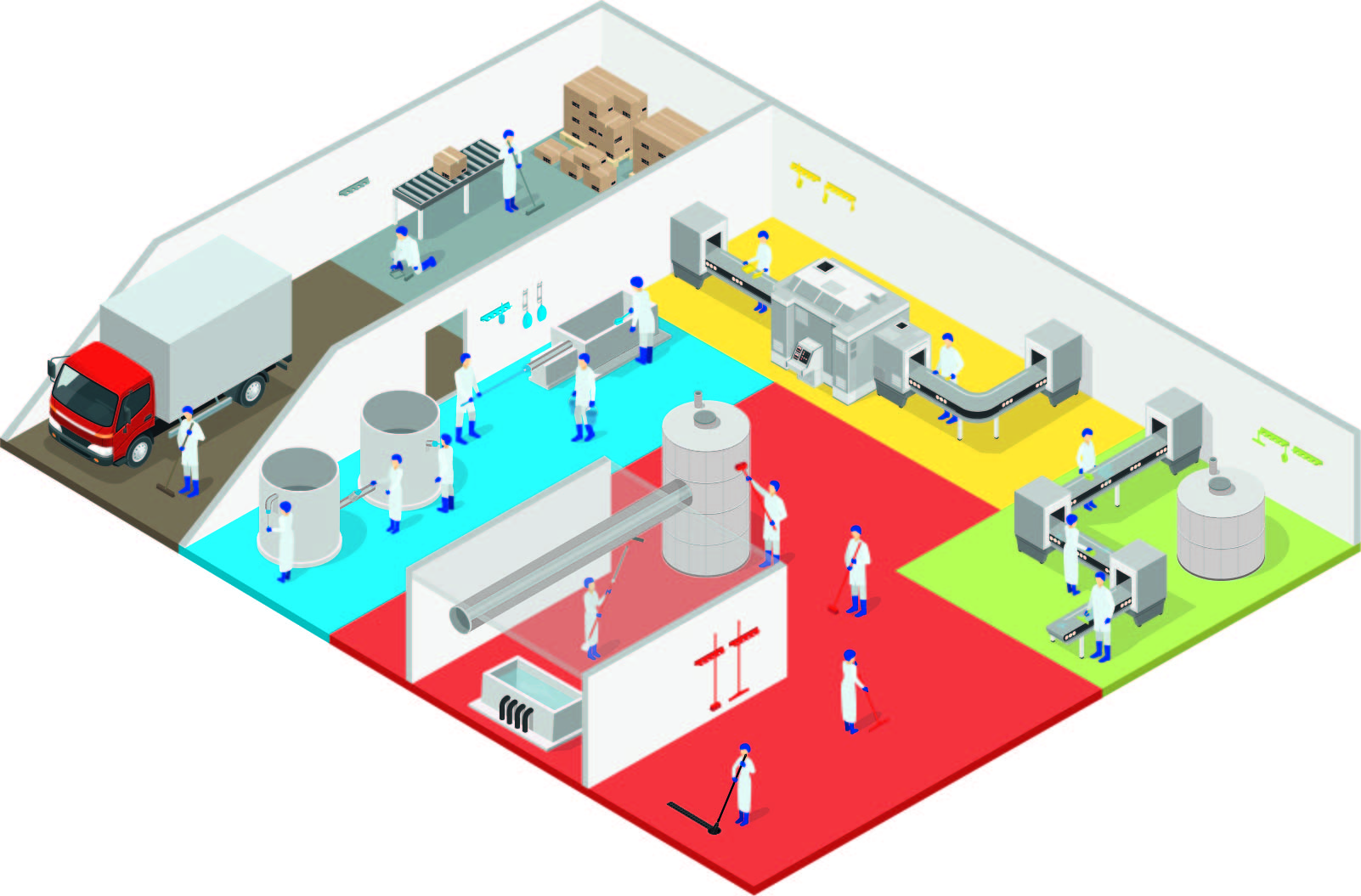

To minimize cross-contamination, it’s ideal to separate allergen production areas and use dedicated equipment. However, this is rare. More commonly, allergenic and non-allergenic production lines are spatially separated, or deep cleaning is done between runs. Color-coding can further reduce contamination risks and support compliance with global standards.

Use of equipment that is "Identifiable and specified for use"

Color-coded cleaning tools provide a visual check to ensure only the right equipment is used. Vikan offers the most comprehensive range of colored cleaning tools, with 12 colors available, including new additions like Brown, Grey, and Lime.

Unusual colors like Orange, Pink, Purple, and now Lime are often used for allergens to make identification easier.

Vikan also provides durable silicone rubber bands in 12 colors. These can be used for secondary color-coding, enhancing segregation and offering greater flexibility. They fit most equipment and can identify vacuum attachments for different uses.

Segregation by color helps ensure that only the correct tools are used in specific areas. For example, using Lime-colored equipment only in the corresponding 'allergen' area.

To further reduce contamination risk, allergen cleaning tools should be stored on color-coded racks or shadow boards. For instance, if Lime equipment is used for sesame, it should be stored on a Lime rack or board. Each allergen should have its own storage space to avoid mixing with non-allergen tools.

Use of equipment that can be "effectively cleaned after use"

Equipment that is hygienically designed is essential for effective cleaning. Both BRC and FSSC 22000 require such equipment. Hygienic design principles include smooth surfaces, no sharp corners, and materials suitable for food contact.

Hygienic design includes:

- No sharp internal angles

- Accessible areas for cleaning

- One-piece construction or easy disassembly

- Smooth surface finish

- Food-grade materials

These principles are outlined in EHEDG Guideline 8, "Hygienic Equipment Design Criteria." Vikan has integrated these principles into its product ranges, such as the Ultra Hygienic and Ultra Safe Technology (UST) lines.

Choosing high-quality, hygienically designed tools, along with regular inspection, decontamination, and replacement, is vital to prevent allergen cross-contamination. It's also important to clean tools before first use, as they may have been contaminated during transport or storage.

Vikan has created a whitepaper to guide customers in maintaining food safety through proper cleaning tool maintenance. You can download it along with additional resources on color coding and hygienically designed brushware.

Color coding guide

Cleaning Tool Maintenance White Paper

Hygienically Designed Brushware White Paper

Minimizing the risk of allergen contamination involves choosing the right tools, using them correctly, maintaining them regularly, and storing them appropriately. The methods and tools selected can significantly reduce cross-contamination. Remember, all cleaning activities can spread contamination.

Here are some top tips for allergen control:

- Choose equipment with good hygienic design

- Clean equipment before first use

- Use color-coded equipment for allergens

- Segregate areas for allergenic food production

- Use methods that maximize cleaning and minimize contamination spread

- Store allergen cleaning tools separately

- Regularly inspect, clean, and replace tools

- Have dedicated allergen spill kits

- Train staff in allergen control

Recent blog posts

BRC v8 hygiene requirements and how Vikan can help

This Blog lists the hygiene requirements within BRC issue 8 and provides information about how Vikan can help with each.

Vikan DoCs – proof of food-contact-safe cleaning tools

Vikan Declarations of Compliance(DoC) are your guarantee that Vikan plastic cleaning equipment and food handling tools contain no toxic substances that could contaminate food. Vikan DoCs are clear...

Cleaning equipment and its importance in the control of Listeria in food production

Get valuable insights from Dr. Phil Voysey to where to look for listeria in a food production and how to prevent cleaning tools from cross contaminating. Learn more about listeria and read Dr. Phil...

Eyebrow pencil,Eyeliner pen,Mascara,eye shadow

Guangzhou Boxuanya Cosmetics Co.Ltd. , https://www.cosmeticsbxy.com